Case Study: Best Window Coverings for Environmental Efficiency

Climate control your home efficiently with window coverings

Windows have been designed to allow daylight and airflow into a building, but they also allow heat gain and loss, requiring adjustments to the energy levels we consume to re-balance the internal temperature. We use window coverings to moderate the amount of daylight and energy consumption, and this study was designed to assess how window coverings are performed comparatively.

We started seeing a lot of claims within the window coverings industry that attempted to claim that window coverings could reduce electricity bills by 80%, 50%, and 40%, and we wanted to check that out.

Classic Blinds and Shutters invests in our product research and development to deliver a superior product for our customers. After an extensive study by Dariusz Alterman and Stephen O’Keeffe into the environmental efficiencies of blinds and shutters, we can advise on the best solution for your home.

Best Window Coverings to Reduce Heat

In simple terms what can you do to reduce heat and light with window coverings:

- Choose white to reflect the heat, and black to reduce light internally

- Plantation Shutters that are fitted in the reveal with frames and seals stop the heat exchange between the hot air behind the window covering and the cooler air-conditioned air in the room. Without a frame and seal the air circulates adding heat to the room.

- The bulkier the window covering the better the thermal blanket.

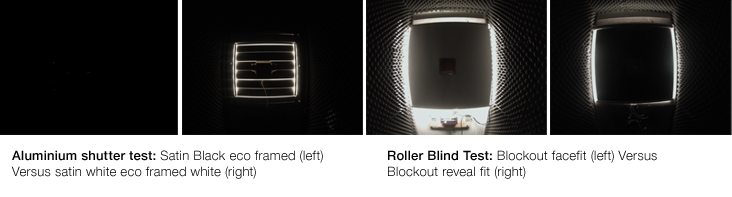

- Face fitted window coverings that reduce gaps deliver best on light leakage.

- Window coverings should be fitted in a way to seal as many air pockets as possible, and reduce as much light as possible coming into the room.

Comparative Efficiency Study

We were aware that there were a lot of extravagant claims circulating, regarding the impact window coverings can have on energy bills. We commonly saw “Reduce energy bills by 80%, 70% or 40%“ and wanted to test the possible accuracy of these claims and use the results to develop and improve our understanding of how window coverings impacted on heat gain or loss and light block out. With this improved understanding, we would be able to advise clients more effectively and improve our own product range.

Stephen O’Keeffe the Managing Director of Classic Blinds & Shutters set up a laboratory engaging academic help to design the test and help with managing the data analysis. Initially Stephen planned to run the experiment for 6 months but due to the high number of window coverings to test it ended up running for 24 months.

VIEW WINDOW COVERINGS STUDY REPORT

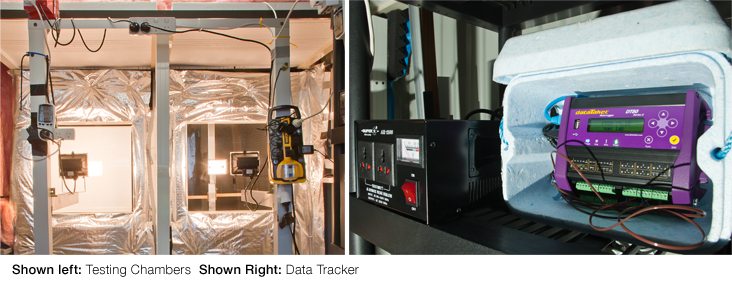

Two identical testing chambers were used, one for testing and one for control. The chambers were constructed from an aluminium frame, polystyrene insulation batts and 3mm plywood. They were then covered with 2 layers of insulation batts to minimize the effect of the external environment. They were then wrapped in reflective foil and covered in acoustic foam and placed within an air-conditioned laboratory. Each chamber was equipped with thermal sensors and a 500W halogen lamps to provide heat and light source to the chamber.

The first testing cell was equipped as the ‘ultimate window covering’ (UWC) – a polystyrene panel 60mm thick, used as a control and to set a benchmark.

The other cell was used to measure and monitor the light and temperature of a variety of window coverings and in what turned out to be crucial, different colours.

At its most simple, the testing was done by creating two identical, thermally-stabilised ‘rooms’. The entire test environment was stabilised with 24-hour air-conditioning to 22C. Two simple heat sources were applied to the rooms with precisely the same amount of heat and a window covering was placed in one of the test rooms to test against the control room.

Data Collection

Temperature Data Collection

A datataker was installed which recorded temperature data at 30 second intervals and ran for 9.5 hours per day. 12030 data points were collected daily

The chambers were calibrated to an accuracy of over 99.5% and subsequently checked at regular intervals.

The control chamber was used without any window coverings and the test chamber was used to test a wide range of window coverings in different colours.

Light Data Collection

Light levels were measured in LUX by a light meter and a thermal camera used to show the visual differences between different coverings

Testing for Heat Reduction

The first window covering to be tested was the Ultimate Window Covering (UWC), a 60mm thick polystyrene insulation batt that fitted snugly into the test chamber’s window. This gave us our benchmark to compare all other window coverings. Generally heat gain or loss from an average house would be 40% through the windows.

The UWC in white delivered a 39.7% reduction of heat when compared to the control chamber over the 9.5 hour period.

This is close to the maximum possible, found from previous University of Newcastle research. The same UWC in black produced a 34% reduction.

We found that colour had an enormous impact, white was much better at reflecting radiant heat ie heat generated from light and black was much better at absorbing light rays.

Plantation Shutters Test and Results

We then went on to test a large number of plantation shutters in two colours made from timber, PVC and aluminium with various fit options, e.g. reveal fit with frame and reveal fit no frame.

The range for white plantation shutters temperature reduction was between 26.5% and 32.1%.

Aluminium revealed fit with eco frame was 27.5%, and PVC revealed fit with frame 30.3%.

When we tested the same plantation shutters in black the results were very different, with a reduction in heat ranging from 19.6% to 10.1%

The first conclusion we came to was that colour was the major driver into how much heat was gained, the lighter the colour the better at reducing heat gain.

Blinds Test and Results

Roller Blind Test Results

We went on to test a range of other internal window coverings and concluded that the bulkier the window covering the better the performance. For example a slimline aluminium venetian in black reduced the heat by only 5.2% and a white one by 18.5%. Vertical blinds were also poor performers ranging from 6.8% to 18.2% depending on colour.

External Blinds Test & Results

We all know that an external window covering is more effective at keeping out the heat than one internally but we thought we should measure by how much more effective it would be.

A simple external blind with a mesh fabric reduced heat by around 25.7% to 30.1% with the best results being achieved by a white external plantation shutter in aluminium at 38.7%.

Results for Light Reduction

Shift workers and families with young children often want to reduce the light during the daytime for sleeping.

It will come as no surprise that we found the darker the colour the better the light absorption and that the window covering with the least amount of gaps delivered the best result in this area.

Our UWC gave the best result with 0.0 LUX as did timber and aluminium black plantation shutters if they were framed. At the other end of the results sat white translucent roller blinds at 349 LUX.

Window Coverings Energy Efficiency

We developed this energy rating system following the comparison study.

We tested a range of products in identical facilities using the same procedures and methodology as outlined in the Report “A Comparison Study of Various Window Coverings” peer reviewed by The University of Newcastle’s consulting arm Newcastle Innovation. The following information outlines the findings of this study

Alternatively come and visit our Parry Street Showroom to discuss how our range of window coverings provide difference thermal efficiencies for your home.

Efficiency Test One

Window covering heat gain into a building.

Results are based on the difference in average temperatures taken over a 9.5 hour period, in two identical chambers. We initially tested the ultimate window covering, a 60mm polystyrene block to set our bench mark of 40%. Then a range of window coverings were tested and compared to a pane of glass. A comparison of the differences in temperature were measured over 9.5 hour period. For example: block out fabric roller blinds reduced the total heat into the house by 18.3% (based on satin white colour). In essence, the higher the percentage represents a better energy efficiency. Note that colour was found to be a major driver with satin white vastly outperforming satin black.

Efficiency Test Two

Window covering heat gain through window only.

Results are based on the difference in average temperatures taken over a 9.5 hour period, in two identical chambers. We initially tested the ultimate window covering (UWC), a 60mm polystyrene block to set our bench mark of 40%. Then a range of window coverings were tested and compared to a pane of glass. A comparison of the differences in temperature were measured over 9.5 hour period. For example: block out fabric roller blinds are 46.1% (based on satin white colour) as effective as the UWC at blocking out heat. In essence, the higher the percentage represents a better energy efficiency. Note that colour was found to be a major driver with satin white vastly outperforming satin black.

Resulting product development

We are always looking to improve our products through our continual research and development.

Our team are always learning and implementing new technologies into our products to improve the overall experience they provide our customers.

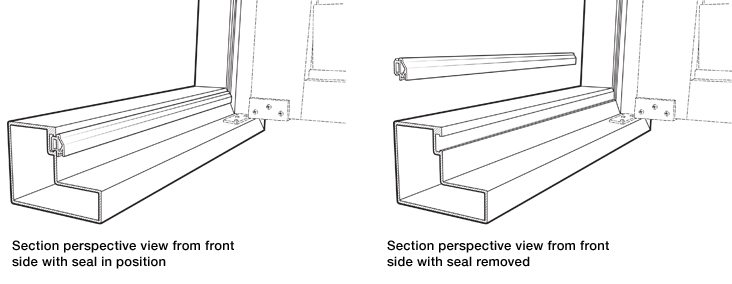

Stephen used the insights he gained from conducting this experiment to work hard on the design of the aluminium plantation shutters we produce in Newcastle. Over the last 5 years Stephen has designed and patented a number of frames and seals that have increased the thermal efficiency of our products. When plantation shutter blades are closed, the rubber seal acts to prevent the movement of heated air into the room.

Update 2019: We have since developed a Classic white aluminium plantation shutter with frame and eco seal which would reduce the heat gain within the test chamber by our estimation another 2-3%.